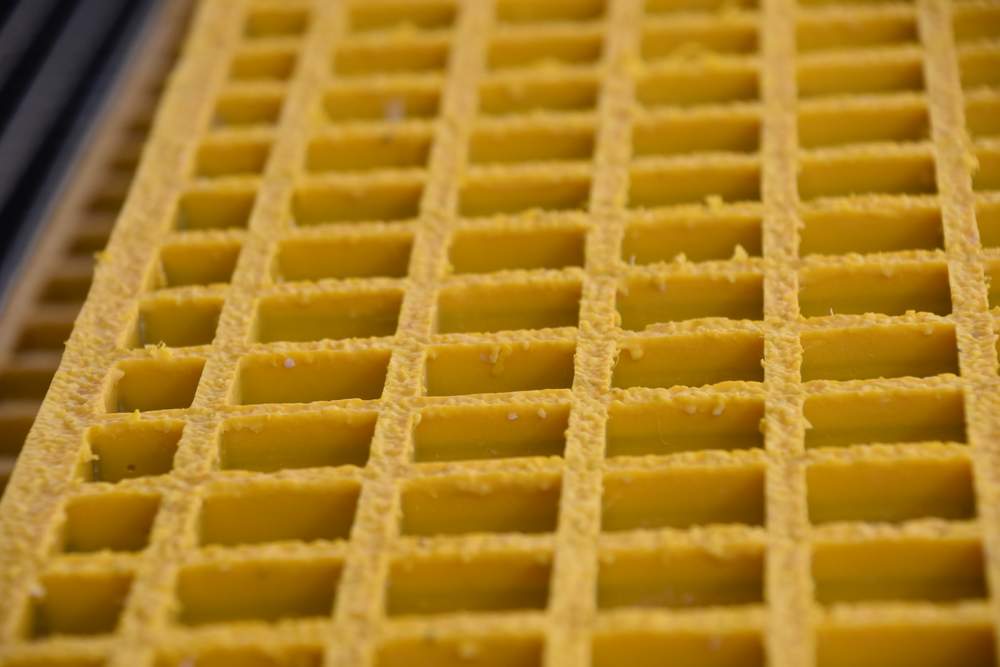

Fiberglass Grating (FRP)

What is FRP grating?

FRP grating refers to products manufactured from fiberglass and resin. There are different types available, but at PITSA, we specialize in molded FRP grating. This type of grating provides excellent mechanical and chemical resistance, making it ideal for industrial applications in areas exposed to spills or environments with high corrosion levels.

What is it used for?

FRP grating is used to create safe walking or driving surfaces, providing corrosion resistance and being up to 50% lighter than steel.

Common applications include:

- FRP pedestrian grating for industrial plants

- Grating to safely cover drainage systems (pedestrian or vehicular)

- Grating for use inside industrial tanks and containers for highly corrosive processes

When should you use fiberglass grating?

While FRP grating offers many benefits, it's important to know when it's the right solution, as using it in low-corrosion environments may be unnecessary.

These gratings are highly recommended for industries where the environment is prone to acid spills, aggressive chemicals, or constant exposure to saltwater or other corrosive factors.

Superior characteristics of molded grating

Unlike pultruded grating, molded grating offers superior tensile strength thanks to its manufacturing process, providing more uniform structural resistance in all directions.

Grating Comparison: Molded vs Pultruded

The following table highlights the key differences to help you determine which option is best for your needs:

| Type | Corrosion Resistance | Mechanical Strength |

|---|---|---|

| Molded | High (depending on the resin) | High, uniform in all directions (multidirectional) |

| Pultruded | Medium to low | High, but only in the direction of the bars |

| Steel | Low, easily corrodes | High, but depends on welding and maintenance |

Detailed explanation

Corrosion resistance

The corrosion resistance of FRP grating mainly depends on the resin selected. We always recommend the best material based on your specific use case. That said, molded grating has a lower chance of corrosion failure due to its solid, homogeneous structure.

Steel grating, by contrast, corrodes easily without constant treatment and maintenance.

Impact resistance

Although fiberglass is naturally more fragile than steel, molded grating is more flexible and has better impact absorption than pultruded grating, making it safer in demanding applications.

Steel offers the highest impact resistance but is heavier and requires constant maintenance.

Mechanical strength

Both types of FRP grating provide high mechanical strength, but:

- Molded grating: Uniform strength in all directions

- Pultruded grating: High strength along the bar direction, lower lateral resistance

The best choice depends on your specific application.

Frequently Asked Questions

Here we answer the most common questions from our customers. If you still have doubts, feel free to contact us at the bottom of the page.

No, fiberglass grating does not rust. It is designed to withstand corrosive environments, unlike traditional steel grating.

Yes, as long as the grating thickness and type are chosen correctly for the load. Contact us for personalized advice.

FRP grating requires little to no maintenance, just periodic cleaning in highly aggressive industrial environments.

Yes, we can manufacture grating to your exact size and material specifications.

Contact Us

Do you have more questions or need a quote? Get in touch with us through the method that works best for you.

Contact a sales engineer

Choose your preferred contact method